Now he can measure and cut each leg to the exact length without using

a tape measure. Once cut to length, each miter angle can be slotted

with a plate joiner - another good job for the apprentice.

Chestnut begins gluing up on a

full sheet of plywood on sawhorses (his sheet is covered with an old

piece of "putrid orange, 1950's-style" matte Formica). He

sets out glue, biscuits, Clam Clamps, hot water and a toothbrush for

cleanup, and an air hose, which he uses to dry off the joint after cleaning.

For glue, he uses red-capped Titebond (not to be confused with the thin,

waterproof Titebond) in a Lamello glue bottle. Chestnut typically glues

up all the casings for the job in one session.

Because of the Clam Clamp's flat

profile, Chestnut can nail the clamped casings directly to the jamb,

if needed. He routinely adds a thin bead of glue to the jamb (especially

near the miter) and brings the casing and jamb together with Quick-Grip

Clamps. Using Paslode's maneuverable, cordless trim gun, Chestnut nails

the inside edge of the casing. The carpenter running baseboard is responsible

for nailing the outside edge.

"The man running baseboard

has the right length nails," Chestnut explains, "and the lag

time allows the glue to set and strengthen the joint before the legs

get pushed and twisted flat to meet the drywall."

Chestnut has sold hundreds of his

clamps, many to carpenters in the area who have seen them in action

with his crews. Clam Clamps run about $55 each. For more information,

contact Chestnut Tools, Box 320094, Fairfield, CT 06825; 203/384-0888.

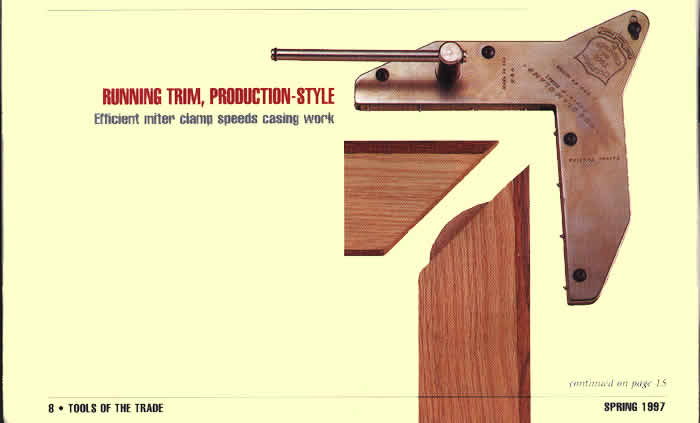

To

speedily glue up plate-joined miters, Chestnut needed a miter clamp, but

could not find one that met his needs. So he built one. The Clam Clamp,

as he calls his invention, works by applying pressure through the clamp's

teeth, using a simple, rugged cam. A single, 180 degree turn is all that's

needed to apply full pressure. The entire clamp is made of a hardened

alloy steel, which has been nickel-plated to prevent rust stains when

the glue joint is cleaned with water.

Here's how Chestnut works with the

clamp for casing out doors: He starts by setting up a cutting station

near his stock, and checks that the miter saw is cutting an exact 45 degree

angle. He then appoints an apprentice to cut the left legs for all the

doors. At this point he is only cutting the miter, leaving the length

long. Then the apprentice moves on to

cut the left end of all the head stock, then on to the right legs.

Meanwhile, Chestnut makes up a cut

list. He starts by numbering each door as #1, #2 etc. The legs are marked

as #1, #1H, #2, #2H, etc. "H" stands for hinge side. Each leg

is measured to the long point. Chestnut carries along a spare piece of

leg stock to check the bottom fir, and notes any special cuts that are

required on his list.

To speed up cutting the legs to length,

Chestnut sets up a stop on his cutting table at a distance that's a couple

inches longer than the average leg length (for example, the stop is set

at 87 inches if the average leg is 85). He then whips out a Quick Rule

(another Chestnut invention). A Quick Rule is a simple, 4" sticker

marked out in 1/16th-inch increments that he slaps on the saw fence.

Reprinted from "Tool of the Trade Magazine"

Spring 1997 pg. 9

![]()

Index of

Videos

No Fees, No Cookies,

No Registration

1 more new

Sept. 24, '06